Color it clean

Vikan pioneered cleaning tool color-coding in the 1990s, and the practice has now become an industry standard, required by food safety standards around the world.

This site is optimized to run in horizontal view. Please rotate your device before continuing.

Requesting a password reset - we will generate a new password and email it to you

Vikan pioneered cleaning tool color-coding in the 1990s, and the practice has now become an industry standard, required by food safety standards around the world.

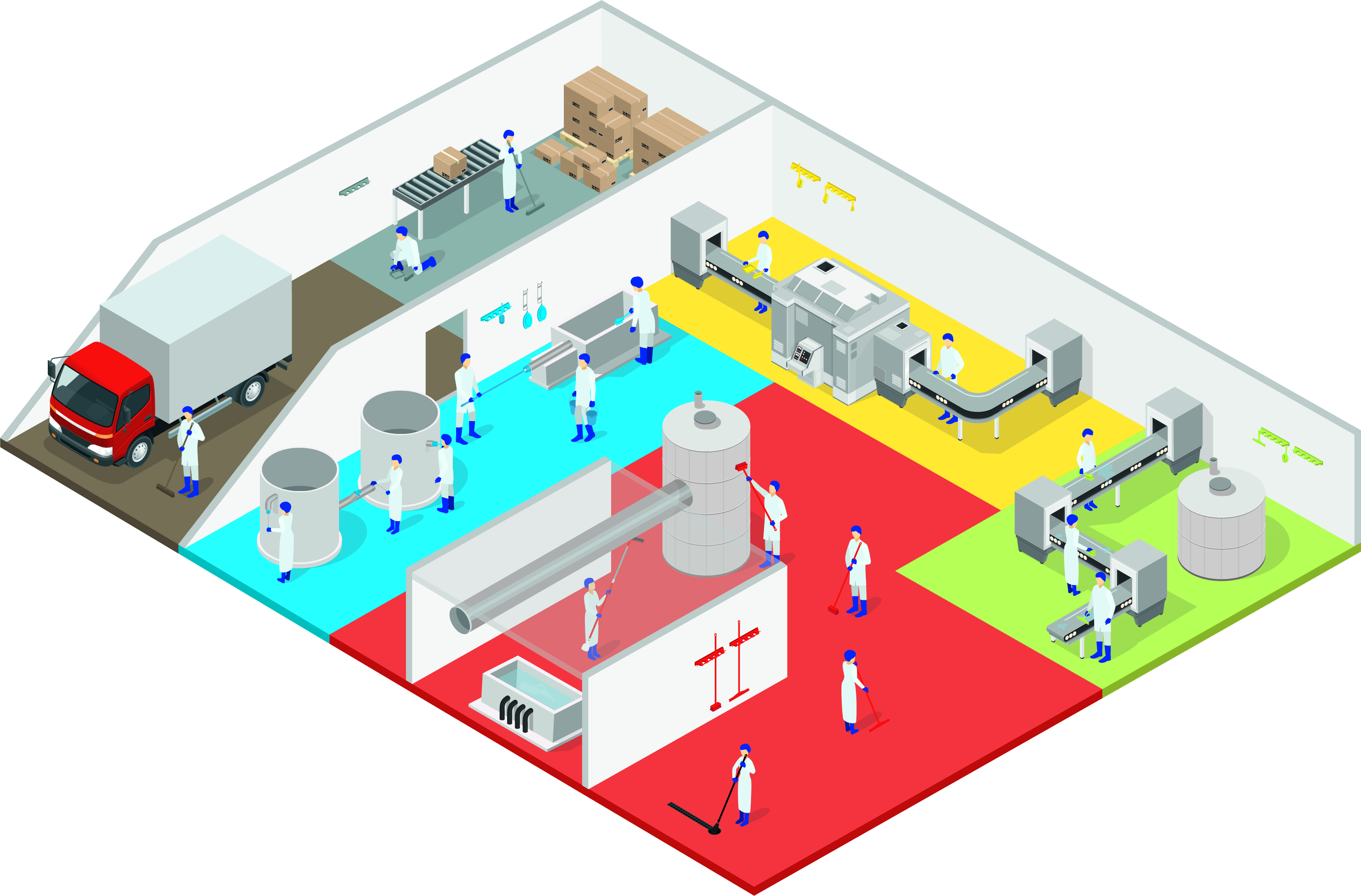

Color-coded segregation helps minimize the risk of product cross-contamination from microbes and food residues, including allergens, chemicals, and foreign bodies. It works by assigning cleaning tools a specific color for use in specific areas and/or for specific tasks.

For example, red tools can be used in high-risk areas, and yellow ones in low-risk areas. Blue tools could be used to clean surfaces that come in contact with food, while green ones could be used for cleaning floors. This makes it easy to identify whether tools are in the wrong area, or are being used for the wrong task.

To find out more about color-coded segregation download the Vikan white paper entitled ‘Guidance on the use of color-coding to improve food safety and quality’.

Vikan can help you get started with color-coding, or update your current plan. We’ll conduct a site survey and develop a hygienic zone plan specifically for your facility – all free of charge. The service also includes a cleaning tool management plan.

Color-coding is easy to implement if done correctly from the start. Vikan’s guide to color-coding gives you a brief introduction to the benefits of color-coding – and some practical tips on how to put it into practice.

Sign up for our newsletter today